This article was published as

Kranthi K.R. 2015. Why this Kolaveri-di syndrome in cotton?. CAI-Vol 31: 3rd November 2015. Cotton Statistics and News, Published by Cotton Association of India, Mumbai

Why

this Kolaveri-di syndrome in cotton?

K. R. Kranthi

On 16th November

2011, A Tanglish (Tamil-English) song ‘Why this Kolaveri di’ sung by film star

Dhanush, went viral on the net. I learnt that ‘Kolaveri’ meant ‘urge to kill’. While

I heard the song, it occured to me that in India, we actually kill good

technologies with a drive for ‘Kolaveri’ over-kill much before they are

destined for a natural death. The genetically modified (GM) Bt (Bacillus thuringiensis) based Bt-cotton

is one such good technologies that is being dragged to the altar due to the

Kolaveri syndrome. Other technologies such as hybrids, new GM genes, insecticides

and fertilizers are also pushed under the Damocles’ sword.

But, we haven’t as yet lost

the battle. Bt continues to do its job of keeping the dreaded bollworms under

control. Despite the hue and cry with whitefly in Punjab, this year, whatever

one might say, India is poised for a good record yield that would get close to

400 lakh bales. I have no hesitation in saying that India could have harvested

more, much more than the current low national average of 500 kg lint per

hectare. How do we do it and when? If China can get 400 lakh bales from 44 lakh

hectares, why can’t India do the same from its 54 lakh hectares of irrigated

cotton out of its total 128 lakh hectares of area under cotton? Whatever cotton

we may get from the remaining rain-fed 74 lakh hectares would be additional

bonus. I realize that many colleagues get uncomfortable with the thought that

the conditions in other countries are completely different and cannot be

compared with India. But, the fact is that India has the best of all ideal

conditions as are required for cotton, -better than those that any country can

ever have for cotton cultivation. In fact the dry regions of Vidarbha and

Telangana with good sunshine, heat units and assured rainfall of 600-900 mm

during Kharif season are ideal for great cotton yields. If anything, many major

cotton growing countries suffer from climate related disadvantages for cotton

cultivation. For example, Brazil has excess rain of about 2000 mm that is not

at all suited for cotton. China has odd rainfall distribution in its cotton

regions and lesser sunshine in its northern regions, which are not actually

good for cotton. There are many such examples, where the yields are high in

regions with climate that is not very suitable for cotton. Then how is it that

these countries harvest more than three-fold as compared to India? The simplest

answer is: short duration varieties. It is easier to fit a short duration

variety into a window where the weather conditions in a short frame of time can

be suitable for its production. The average range of cotton duration in the

major cotton growing countries such as China, US, Australia, Mexico and Brazil

is about 140 to 180 days. Indian cotton is cultivated for 180 to 240 days. Some

farmers even extend the crop all round the year. I dwelt on this aspect in my

previous articles. I firmly believe that the answers for India’s cotton

problems are: short duration varieties + early sowing + resistance to sap

sucking pests + compact architecture + high density planting of at least 40,000

per acre. If the varieties are endowed with any good technology such as Bt, we

win the battle hands down, primarily because it helps in working into the

mindset of farmers who have seen the Bt benefits for bollworm control. Farmers

wouldn’t be worried about bollworms and it would be easily possible to grow the

short duration, sucking pest resistant Bt cotton varieties with least chemical

inputs for very high yields. While ICAR-CICR is working its way to give shape

to these ideas, let me get back to the Kolaveri syndrome again, with an idea to

sensitize whoever matters on what is going wrong in the cotton fields in India.

THE

HYBRID SATURATION KOLAVERI

With 95% area under

Bt-cotton and more than 1600 Bt-hybrids, the technology developers and the seed

companies are overzealously hell bent for overkill –The Kolaveri effect. Knives

are getting closer to the golden goose. These days, hundreds of hybrids are

created each year, but most of them die as a name even before they are born. It

looks more like a lottery ticket. When any one hybrid clicks, the company goes

full throttle for a couple of years. Then one fine day the hybrid is replaced

by another lottery winner. Many a times, scientists are asked as to why a set

of package of practices are not standardized for the Bt-hybrids. I wonder, if

this could work at all, with hundreds of new hybrids with odd characteristics

of differing growth habit, different duration under different conditions and

all of them competing with each other for the same space? It is difficult for

any scientist to standardize any kind of package of practices for such

ephemeral systems where even the best of hybrids do not live for more than 3-4

years and are replaced with new ones. But that is not all. Saturation of the

entire cotton area with Bt-cotton hybrids, without any non-Bt cotton as

refugia, is part of the over-kill. Surveys conducted by ICAR-CICR showed that

there were only a few standard companies who were packing proper non-Bt hybrid

seeds in a 120 g pack that are provided with the 450 g pack of Bt seeds. While

others tossed the refugia into the sky. Some of the non-Bt refugia seeds had

very poor germination, some were F-2 Bt seeds, some had varying proportions of

Bt:non-Bt seeds, some were of Gossypium

arboreum. One company even supplied Gossypium

herbaceum in the 120 g pack as

refugia seeds in north India. The common refrain is that farmers are not

serious about refugia. There is clear evidence with ICAR-CICR that many seed

companies are also not serious about refugia. This over-kill with scant regard

for regulatory guidelines does shorten the life of the technology itself.

With more than 1600

Bt-hybrids the problems of insect pests become acute with so many hybrids in

the same village or the same region, because of the continuous availability of

vulnerable plant parts such as tender foliage, squares and flowers in one or

the other hybrid within a narrow geographical range, which actually attract and

sustain a number of insect pests. Insect hot spots develop in the regions and

spread all over.

THE

BOLLGARD-II OVER-KILL

When Bollgard-II was introduced

into the market, our observation was that some of the ‘Bollgard single gene

Cry1Ac based hybrids’ were actually much better than the corresponding ‘double

gene Cry1Ac+Cry2Ab Bollgard-II hybrids’ of the same brand. The Bollgard hybrids

were relatively stable and uniform. It is quite likely that the overzealous

over-drive of the technology providers to replace Bollgard with Bollgard-II,

may not just be because of the technological advantage of the two gene product,

but IPR issues may have played a role. Seed companies were in a competitive

race to launch their new BG-II hybrids in a rapid fast-forward mode in a bid to

capture the market early. This went for a toss. Though BG-II was approved in

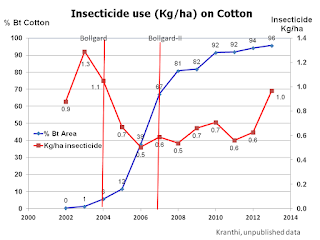

2005, the area under BG-II increased from 8% in 2007 to 90% in 2012. It was

this rapid replacement of BG with BG-II that may have unsettled the cotton

scenario. An assessment of the hybrid qualities on the field showed that there

are many companies who were actually not geared up to develop good quality

homogenous BG-II hybrids. Handling two genes to develop homozygous parent

material, identification of good heterotic (hybrid) combinations, testing their

suitability for various agro-eco regions and development of commercially viable

BG-II hybrids in a short time is a technological challenge that many seed

companies are not properly equipped with. As a result the market was flooded

with half-baked products introduced in a mad-rush in a cut-throat competition.

The results are there for everyone to see. There was a reasonable good progress

during the years 2004 to 2007, but the scenario was disrupted during 2007 to

2012.

Scenario

during 2004 to 2007

1.

The area under BG Bt-cotton increased from

5.7% in 2004 to 67% in 2007. 92% of the Bt cotton area was under the single gene

BG hybrids.

2.

A total number of 62 Bt hybrids were approved

in 2006 and were available in 2007.

3.

Cotton yield increased from 453 kg/ha in 2004

(6% Bt area) to a National record of 567 kg/ha in 2007.

4.

Insecticide usage declined from 1.12 kg/ha in

2004 to 0.6 Kg/ha in 2007.

5.

Expenditure on insecticide decreased from Rs

1543/ha in 2004 to Rs.1238/ha in 2007.

6.

Fertilizer usage increased from 98 Kg/ha in

2004 to 140 kg/ha in 2007.

Thus the data clearly show

that until 2007, yields were on the rise, insecticide usage on cotton was on a

decline and fertilizer use had marginally increased. The scenario changed

drastically within four years after 2007, a period that was characterized by a

total replacement of BG with BG-II. Was this sudden massive replacement

beneficial to the cotton farmer? Data from the Ministry of Agriculture,

Government of India showed that during the period 2007-2012 input usage

increased drastically as also reflected in high cost of production. The figures

1 to 7 show the trends in insecticide usage, fertilizer usage, yields and

production cost. The following points highlight the drastic changes in inputs

and the yield decline during the period 2007 to 2012.

Scenario

during 2007 to 2012

1.

The area under BG-II increased to 90% of the

Bt area in 2012 from a meagre 8% in 2007.

2.

The number of Bt hybrids increased from 62 in

2006 to 1097 in 2012.

3.

Yields declined from 567 kg/ha to 496 Kg/ha

in 2011 (CAB data).

4.

The National average expenditure on fertilizer

increased from Rs 2400 per hectare in 2007 to Rs 7400 in 2012.

5.

Fertilizer quantity increased from 140 kg/ha

in 2007 to 222 kg/ha in 2011.

6.

Seed cost was Rs 1793/ha in 2004, which

increased to Rs 2023/ha in 2007 followed by a massive increase to Rs 3842/ha in

2012.

7.

Insecticide usage increased from 0.6 kh/ha to

0.96 kg/ha in 2013 (Kranthi, unpublished data)

8.

Expenditure on insecticide increased from Rs

1238/ha in 2007 to Rs.2417/ha in 2012.

9.

Cost of cultivation increased from Rs

23,987/ha in 2004 to 29,196/ha in 2007, but increased drastically to Rs

63,751/ha in 2012.

Thus it is now becoming

clear that introduction of a new gene does not necessarily mean that farmers

would be benefitted. There is no doubt that the unwarranted over-kill to launch

one thousand hybrids within the 5 year period during 2007-2012 also may have

unsettled an otherwise probable positive growth curve. If this is not Kolaveri,

then what is?

THE

INSECTICIDE KOLAVERI

Commercial chemical and seed

companies ‘make hay while the sun shines’. They instantaneously burn the hay

into ashes too. Insecticides such as imidacloprid could have been a very useful

tool if retained only as cotton seed treatment. But the spray formulations of

the neonicotinoid group of insecticides such as imidacloprid, thiomethoxam,

acetamiprid, clothianidin etc., went for an over-kill. Today almost all the

sucking pests have developed high levels of resistance to the entire class of

neonicotinoid insecticides. Sucking pest infestation is high at just about the

squaring and flowering period. Neonicotinoid sprays at the flowering time harm

pollinators especially honey bees. With just seed treatment and without foliar

sprays of neonicotinoids, we could have preserved the efficacy of this group of

insecticides in an ecologically acceptable manner. This isn’t the first time

that we killed a technology with the Kolaveri syndrome. Synthetic pyrethroids

were killed with the Kolaveri factor of rapid indiscriminate overuse to the

point of death. Many other useful insecticides such as spinosad, emamectin and

indoxacarb are also getting into the Kolaveri clutches. Insect resistance to

insecticides prompts farmers to resort to higher doses and excessive repeated

usage. This continues finally into cocktail tank mixtures of several groups of

insecticides. Disaster follows -as was seen in Punjab this year.

It must be remembered that,

somewhere in a dark alley, some worms are waiting for their turn, while some

arrive and have a field day. The whitefly made a grand early entry this year and

painted Punjab red and blue. Farmers were unanimous that more they sprayed -more

were the flies that came back with vengeance. While the tiny insects leave a

bloody mark all around like a powerful enemy, the battle field looks deserted

without any semblance of defence. All insecticides failed. Most of the

insecticides, especially the cocktails mostly killed the beneficial natural

enemies that keep the whiteflies under check, and couldn’t control whiteflies

because these insects hide under the leaves and have a protective waxy coating.

Thus, it may be probably correct to say that the enemy used up insecticides for

their advantage for resurgence and outbreaks. Waiting in the wings, the pink

bollworm is bracing itself up for the next great innings starting this week in

Saurashtra belt of Gujarat. The un-sustainability factor runs high. As new hybrids

come and go one after another, new insecticide molecules are also on a high. Nobody

knows how the new hybrids behave under the changing climate and also with

interventions of new chemicals. Many a time new insecticide molecules may cause

critical disruptions in ecological balance by devastating the naturally

occurring biological control and cause resurgence of insect pests. The recent

case of the whitefly could have been because of one or two new molecules that

were released recently and were used extensively during the past three years,

albeit more in Punjab. There is a need to do a ‘Sherlock Holmes’ to unravel the

mystery of the whitefly menace in Punjab. Though not unexpected, there are many

surprise elements in the story. Some explanations seem plausible based on

experimental results, but reasons for the humongous scale of damage need to be carefully

unravelled. Was it just susceptible hybrids? Was it late sowing? Was it the early

hot and humid weather? Was it excess urea? Was it indiscriminate insecticides?

Or, was it a combination of any of these factors? Or could it be just the

overuse of any particular new insecticide that may have been introduced recently

and used extensively either alone or in tank mixes. Why this Kolaveri, and

until when.

As many in the seed

industries still naively wait for that unknown miraculous gene, something like

the Cry1Ac, which could turn their fortunes overnight. But, there seems to be

nothing in sight which can now cause a breakthrough for high yields.

Unfortunately, the dreams of many seed companies now seem to be driven only by mirage

of new genes, that too from lands, far away. The Indian seed companies seem to

be waiting for the knight in shining armour, the only hope, the hero on the

white horse from yonder lands to rescue their business. Seed companies were

indeed banking on new genes in the form of Bollgard-III or wide-strike or twin

link or round-up ready flex and on and on. On the same side of the fence but

knights of a different kind, the pesticide companies were depressed for a

while, but not anymore. The silver lining expanded and for them -happy days are

here again. One after another, insect pests take turns to bring cheers to their

business. The mealy bugs, thrips and jassids kept them in good humour until

recently. The whitefly returned and signed blank cheques for the insecticide

industry. And, now the bollworms are likely to be back in business soon. No

wonder the cotton crop is repeatedly forced to listen to the Kolaveri song.

Which new genes, new technologies

have the potential to break the stagnant yield graph of India, no one knows. But,

it is clear that the questions are tough and the challenges are rough. The

commercial technology providers seem to have lost the plot. But we must not

lose hope. All of us in the public and private must work together to bring

cheer to the farmer. There is a need for robust solutions that will lead us to

sustainable cotton farming for high yields with low inputs. From the Kolaveri

song we must move over with hope to our old but beautiful song “We shall

overcome, we shall overcome, we shall overcome one day.”